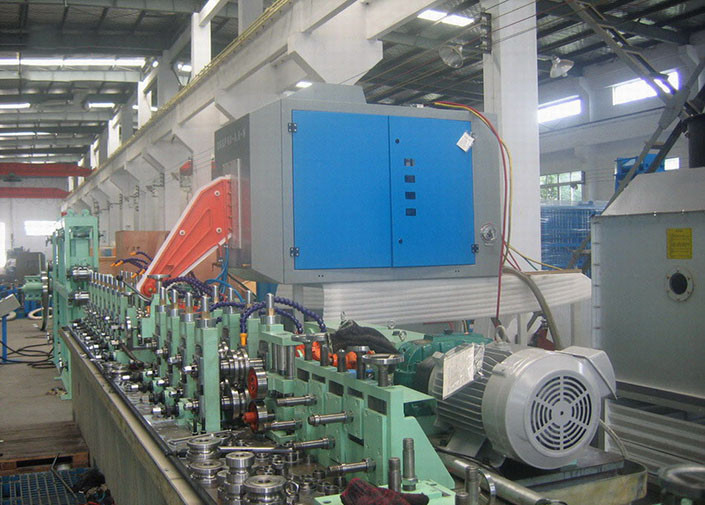

90m/Min Welded Tube Mill VZH-32z , High Frequency Weld Pipe Mill Machinery

Stainless Hydraulic Tubing Welded Tube Mill With Steel Pipe Production Line

Quick Detail:

1. Type: welded steel pipe production line

2. Model Number:VZH-32z

3. Used in: VZH-25 unit is mainly used for the production of low-pressure fluid, such as water, gas pipes pipe; boiler tubes; mechanical parts, frame tube, fitness equipment tubes, furniture tubes, pipes and other thin-walled structures decorating tube

Description:

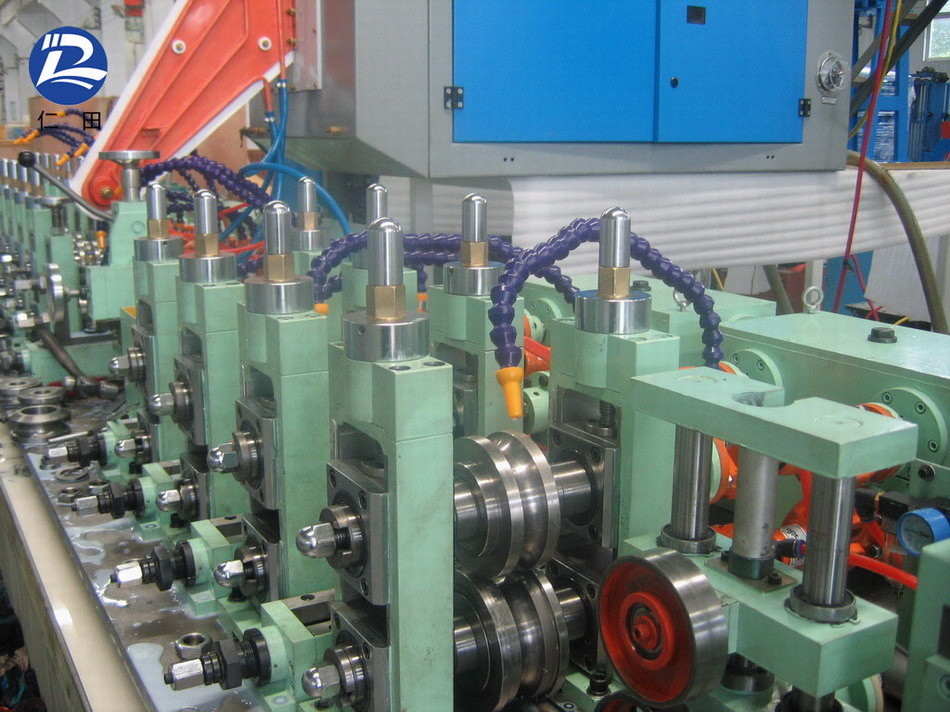

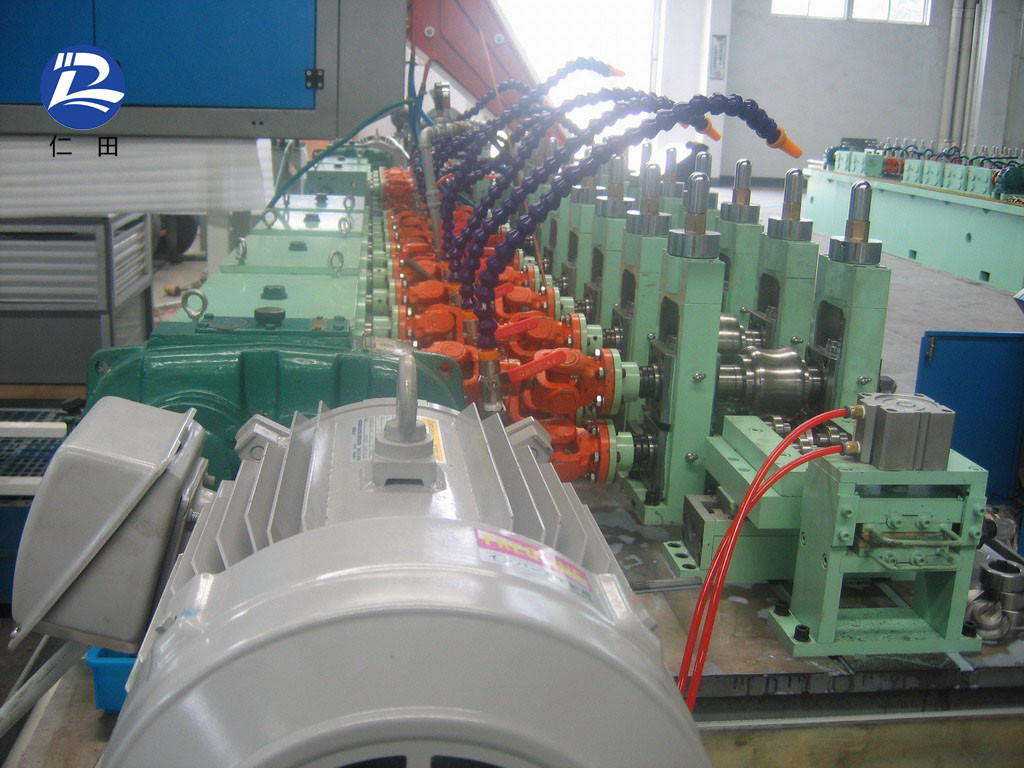

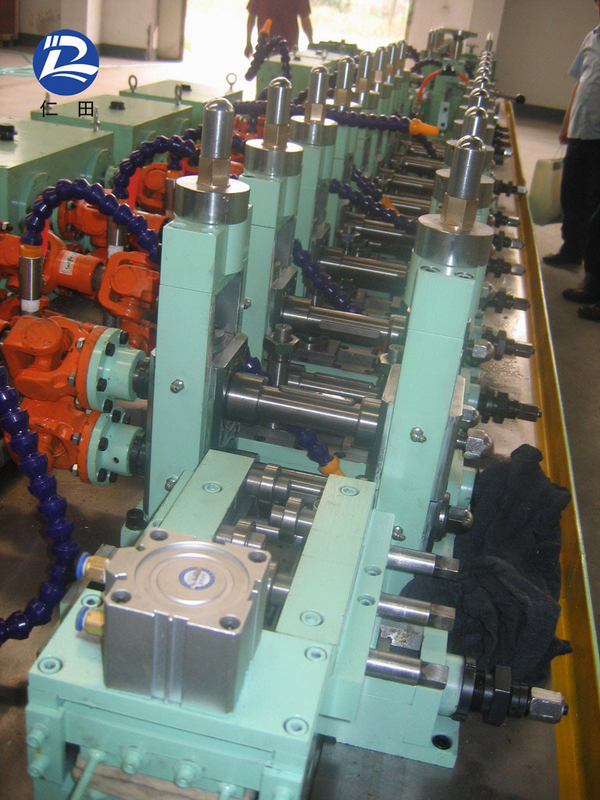

Tube mill are designed to produce round tubes with Diameter 7mm~273mm and shaped tube(square & rectangular), the tube mainly applied in manufacturing middle-pressure fluid tubes, boiler tubes, gas pipes, galvanize pipes, transformer tubes, mechanical parts, frame tubes, fitness equipment pipes, furniture tubes, decoration tubes, etc..

Basic configuration:

Double-heads uncoiler→Shearing machine & Butt welding machine→Vertical cage→Forming machine→High frequency induction welder→De-burr frame(Outside) →Seam grind unit→Cooling trough→Sizing mill→Turkey head & Straightening→CNC flying saw→Run-out table.

Applications:

Specifications:

|

NO

|

Name

|

Technical Parameters

|

Unit

|

|

1

|

Tube OD

|

12.7--38.1

|

mm

|

|

2

|

Tube Wall Thickness

|

0.5-1.75

|

mm

|

|

3

|

speed

|

20-90

|

M/min

|

|

4

|

Main Power

|

45*2

|

kw

|

|

5

|

HF welded

|

100

|

kw

|

Competitive Advantage:

Installation, commissioning, training, after-sales service

1,Installation and acceptance

1.1 After the machinery from the supply side to the demand side, the demand side is responsible for unloading facility.

1.2 Supplier is responsible for the mechanical commissioning.

1.3Demand side should accept the machine after bending specimens according to demand’s request (subject to the requirements of the contract)

2,Training

Train to all the adjustment workers, operators, maintenance workers (hydraulic, pneumatic lubrication system maintenance personnel, electrical, electronic and control systems personnel, CNC programmers, technical staff),to make sure they can operate, adjust, repair, programming properly.

3,Service.

3.1 Quality "three guarantees" period: 12 months form the commissioning date of acceptance by the demand side

3.2 During the "three guarantees" period of equipment failure, the supplier is responsible for free repair, replacement parts (except for the demand side in violation of the rules of accidental damage caused).

3.3 Responding to the supplier to provide services required by the buyer receives telephone (fax) the day after, within 48 hours (except holidays) sent to the demand-side scene.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!